Building a new workshop

A new workshop is currently being built for the safe operation of the repository until its decommissioning. It is located on the 2nd level near the shaft in a part of the mine which will be the last one to be sealed in the scope of decommissioning. The previous workshop is located in the control area of the repository. Its operation is not cost efficient, since vehicles need to be cleared after they have been maintained and/or repaired, which is costly and time-consuming. Only then are they allowed to leave the control area of the repository.

Purpose of the new workshop

A workshop underground is needed for the repository operation and the then following decommissioning. Machines and vehicles are maintained and, if necessary, repaired in this workshop.

The previous workshop is located in the control area of the repository on the 4th level, where radioactive waste had been stored formerly. Today, a major part of operational work is carried out on levels 1 to 3. After having been maintained and repaired, vehicles that are used outside the control area need to be cleared. Depending on the vehicle, this takes up to two weeks and causes high cost and effort.

The new workshop is located in mining district 1s on the 2nd level of the Bartensleben mine directly by the shaft. Later on, its floor area will cover ca. 2,000 square metres. The mining district is located in a part of the mine which will be the last one to be sealed in the scope of the planned decommissioning. This ensures that it will be possible to use the workshop during the decommissioning phase for as long as necessary.

Current works

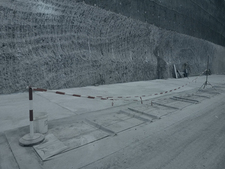

![]() Concrete slabs for workbenches and lathes as well as covered maintenance and assembly pit

Concrete slabs for workbenches and lathes as well as covered maintenance and assembly pit

![]() Container for training workshop and office spaces

Container for training workshop and office spaces

Following its clearance, the floor of the mine has been extensively paved. Two containers have been installed for future use as training workshops, materials storage and office spaces. The containers are currently being furnished.

Concrete slabs have been laid in a small part of the workshop. These provide a stable and resistant foundation for larger workshop tools such as workbenches and lathes. A maintenance and assembly pit has been created directly alongside, following strength tests of the suspended load between the 2nd floor channel and floor channel 3a, which lies beneath it. The pit enables repair works underneath machinery and vehicles.

Completed work

Preparation of the mining district

![]() Roadheader in the new workshop

Roadheader in the new workshop

Before one could start carrying out the actual works for the construction of the new workshop, the mining district part of which had been backfilled with debris, had now to be filled completely with salt grit. Thus, a new surface was created from which it was easy to reach the roof of the mining district. This was initially recut with a roadheader and subsequently secured with anchors and nets.

Exploration of the pillar

The pillar between mining district 1s and the 2nd and 2a-level above is between 7.35 and 7.80 metres thick. The pillar was explored by means of three drillings and ground radar measurements. To guarantee safe operation, one will continue to geo-technically monitor the pillar, which has been secured meanwhile.

Construction of the overhead crane system

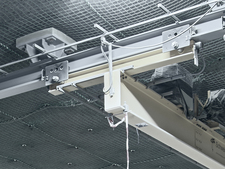

![]() Suspension for the crane system with consoles and anchors

Suspension for the crane system with consoles and anchors

![]() Completed overhead crane system

Completed overhead crane system

From the end of October until December 2013, 184 boreholes, each of which 2 metres long, were drilled for the anchors of the suspension for the crane system. Subsequently, 46 consoles, each with four anchors, were attached to the roof. For this purpose, a special mortar was at first pressed into the boreholes; subsequently the anchors were installed. In January 2014, the solidity of the anchors was demonstrated with tensile tests at selected anchors.

At a later stage of the works, the overhead crane system was installed with two-track crane and two single girder suspension cranes with 10 tons of lifting capacity each. The completed crane track is 70 metres long and 10 metres wide. Once the mining district has been emptied, it will have a lifting height of ca. 12 metres.

Clearing the mine

Following the completion of works to the roof of the mine, the salt material previously brought in was removed. A total of almost 31,000 cubic metres was moved.

State of 2016.05.04