-

Latest news

subnavigation

Latest news

- More messages

- Events

- Statements

- Current works

- Vertical sealing element

- Building a new workshop

- Hoisting tower facade

- More messages

Large-scale project vertical sealing element

Purpose of the large-scale project

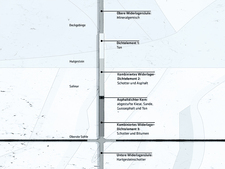

![]() Schematic sketch of the shaft sealing systems

Schematic sketch of the shaft sealing systems

The concept for the decommissioning of the repository contains three vertical sealing elements for the long-term stable sealing of each shaft. It is planned for the uppermost sealing element to consist of bentonite (clay). In mining practice, clay seals have been used for years for the sealing of shafts. The two lower sealing elements are to be fabricated from gravel and bitumen as well as from gravel and asphalt.

Combined abutment sealing elements from gravel and bitumen as well as from gravel and asphalt (bitumen containing additives) are new developments. In the case of these sealing elements, the settlement-stable hard stone gravel column transfers the loads. The bitumen fills the cavities in the gravel and takes over the sealing function. Both components, gravel and bitumen, have been tried and tested as single elements in the keeping of shafts. A combination of both elements is used for the first time.

In the large-scale project in the Morsleben repository, findings from laboratory and technical trials (prototypes at a scale of 1:3 up to 1:5) and from a large-scale project at the surface will be adapted to the conditions in situ. The large-scale project is to demonstrate that the materials can be managed and produced under mining conditions underground.

The large-scale project is scientifically accompanied by the Technische Universität Bergakadamie Freiberg. The Deutsche Gesellschaft zum Bau und Betrieb von Endlagern für Abfallstoffe mbH (DBE) that is commissioned with the management, performs the project on behalf of the BfS.

Current works

Manufacturing of the sealing element underground

On the lower abutment, which has already been produced, a ca. 0.5-m thick compacted gravel layer is placed as foundation, which is then interspersed with salt concrete. A geo-membrane with geotextile on top is placed on this, the geotextile being a textile layer that is impermeable to water. On top of this, a ca. 1-m-thick layer of Bento grit (mixture of sandy grit and clay dust) is installed as filter layer. This layer is again covered with geotextile. The task of the filter layer is to prevent the bitumen from flowing, the bitumen being particularly fluid when hot.

The planned combined demonstration structure for an abutment sealing element is 6 m high and consists of 12 layers of compacted gravel with a thickness of ca. 0.5 m, each layer being backfilled with asphalt which is 170 to 190 degrees Celsius hot. The bitumen is potted according to potting patterns that have been determined as a result of the surface large-scale project that has already been completed.

At the surface, the delivered bitumen is heated in an asphalt cooker. So, the asphalt amounting to ca. 2.5 m3 which is needed to backfill a gravel layer is available. The asphalt is reloaded into small so-called melting-pots to be transported underground. A melting-pot contains ca. 0.5 m3. In the receptacle, the asphalt can be heated and stirred, so that the required pouring temperature of ca. 170 to 190 degrees Celsius will be maintained safely.

Instrumentation

Before bringing in the gravel, two measuring chains with ca. 20 temperature sensors each are installed at the blind shaft. Furthermore, eight pressure sensors above the filter layer of Bento gravel are installed on the geotextile directly under the sealing element. In the process of constructing the sealing element, nine further temperature sensors are placed in the gravel bed in a height of 2, 4 and 6 metres.

The sensors measure the temperature distribution and its temporal change inside the gravel layers potted with bitumen and at the rock wall. Furthermore, combined pressure-temperature sensors measure the pressure deep down in the abutment sealing element. With each layer of pottered layers the pressure should increase, since bitumen acts like a liquid. Thus, the functionality of the produced sealing element can be demonstrated.

Completed works

![]() Large-scale project at the surface for a vertical sealing element

Large-scale project at the surface for a vertical sealing element

Large-scale project at the surface

To demonstrate the material features and functionality of the combined abutment sealing elements of gravel and bitumen and/or asphalt set out in the plans, several trials were executed. In 2013, the BfS tested the pouring of bitumen in gravel layers in a large-scale project at the surface. Based on monitoring data, the individual pouring tests were analysed and their success was evaluated. This way, important experiences could be gained for the large-scale project underground.

Preparation of the large-scale project underground

Among others, the construction site set-up included the following activities:

- The removal of existing equipment in the IB blind shaft,

- The installation of winches for person and material transportation required for the construction of the structure,

- The facilities for the auxiliary ventilation of the working area,

- Mine survey of the blind shaft and marking of thickness of the gravel layers to be constructed.

Construction of the lower abutment for the large-scale project underground

The IB blind shaft has a nearly even square cross-cut with a surface of ca. 11.6 m2. Thus, the IB blind shaft is sufficiently suitable for demonstrating to scale that the production of a gravel-bitumen sealing element in a mine is technically feasible.

The lower abutment consists of gravel that has been potted in layers and compacted. The positional stability of the gravel was reached at the natural angle of slope of ca. 40°.

State of 2016.10.04