The sealing structures according to the decommissioning concept

The decommissioning concept for the Morsleben repository provides for the sealing of the two shafts in a manner that is safe for the long term and the wide, complete backfilling of still open cavities with salt concrete. This is to prevent a possible inflow of water into the mine workings.

In case relevant volumes of influent solutions enter the mine – which is not very probably but needs consideration as well – the emplacement areas eastern field and western-southern field are additionally separated by the other mining districts by sealing structures. Thus, isolated areas which will be dense for the long term will be created in the large and complex mine openings.

These measures need to be implemented because the Morsleben repository is a former exploitation mine and there is thus no continuous and isolating host rock, which would be necessary for a repository. The necessary long-term safety of the repository following decommissioning is ensured by a multi-barrier concept. Apart from the natural barriers, technical barriers are an important component of this concept.

The design of the sealing structures

It is planned to construct sealing structures at 21 locations in the mine openings, with the help of which it is planned to seal galleries near the emplacement areas. The objective is to hinder the inflow of brines into the emplacement areas for the long term. The inflow of saline solutions into the emplacement areas and the pressing of radioactive solution is delayed by the sealing constructions for such a long period that in particular the radionuclides with short decay times will then have decayed to a wide extent. Except for one sealing structure located in the anhydrite, all sealing structures will be constructed in rock salt.

Solely construction materials are used for the construction of the sealing structures whose material characteristics have been examined beforehand. Following laboratory tests and so-called pilot-plant tests – i.e. test set-ups at a scale of 1:3 to 1:5 – the use of the construction materials, the construction of the sealing structure and the results achieved (such as density) in comparison with the planning are tested at a scale of 1:1. The successful construction of the sealing structure and the verification of the planned parameters for the construction materials and the sealing structure are part of the evidence for the safe decommissioning of the repository. The findings gained in this context are used to improve the construction technology and sealing structure parameters and the planning steps still to be carried out.

Sealing structures in rock salt

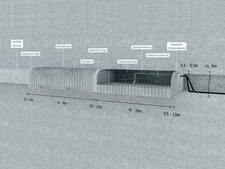

![]() Graph depicting a sealing structure in rock salt (in German only)

Graph depicting a sealing structure in rock salt (in German only)

Salt concrete is used for the sealing structures in salt rock. Salt rock reacts to a mechanical load by slow, fluid movement which is referred to as "creeping". Over time the sealing structures will entirely be enclosed by the rock salt.

The sealing structures consist of one or several sealing segments with single lengths of 25 to 30 metres. In at least one segment per sealing structure, the construction joint between salt concrete body and the surrounding rock salt will be backfilled with a special concrete suspension. This injection prevents the leakage of solutions alongside the contact zone between sealing structure and surrounding salt rock, when the construction joint is not yet sealed by the creep movement of the salt rock.

Sealing structures in the anhydrite

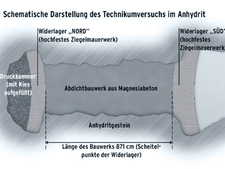

![]() Diagram of the pilot-plant test in the anhydrite (in German only)

Diagram of the pilot-plant test in the anhydrite (in German only)

As opposed to rock salt, anhydrite does hardly deform under load. It shows brittle deformation behaviour which is typical of crystalline rocks, e.g. granite. As anhydrite does not "creep", a different concept needs to be pursued for this sealing, using swellable magnesia concrete.

The swelling pressure of the magnesia concrete is to be held for the long term and, thus, ensure the dedicated positioning of the sealing structure in the anhydrite. In case of an inflow of solution up to the sealing structure, this positioning is to take care that the sealing cannot move. At the same time the solution is prevented from flowing around the construction.

Application in practice

For the construction materials applied in both tests, studies on the material characteristics under laboratory conditions are already available. They show that all assumptions on the structure characteristics are confirmed under laboratory conditions. Application of the construction materials in practice and on a large scale is currently being put to the test.

Test in rock salt

![]() Instrumentation of the test set-up: Among others, the cladding tube can be seen in the foreground, with the inflow and outflow pipes to the injection rings

Instrumentation of the test set-up: Among others, the cladding tube can be seen in the foreground, with the inflow and outflow pipes to the injection rings

With the sealing structure set up in rock salt (a so-called in-situ test) it is shown that it is possible to construct the gallery sealings in a quality-assured manner. On account of the stabilisation measures carried out in the central part from 2003 to 2011, the Federal Office for Radiation Protection (BfS) already has comprehensive experience with the handling of salt concrete as in-situ stabilisation material.

A first test section has concluded. Final results on this are available and are currently being examined. First test results confirm the characteristics previously assumed on the basis of calculations. Among others, the technically demanding injection of the construction joint (backfilling with a special concrete suspension) could be successfully demonstrated. Furthermore, it already shows today that the structure characteristics continuously improve with time on account of the creeping rock salt, as had been anticipated. The test is continuing at present.

Test in the anhydrite

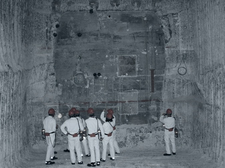

![]() Front side of the sealing structure with visible drillings to examine the structure

Front side of the sealing structure with visible drillings to examine the structure

In a similar way to the test in rock salt, the BfS also intends to prove the suitability of a sealing structure in the anhydrite before it will actually be applied in the repository the scope of decommissioning. As opposed to the salt concrete used in rock salt, little data on magnesia concrete from practice is available.

In the Bleicherode salt mine, a site compares to the Morsleben repository, the BfS has therefore constructed a sealing structure in the anhydrite. One objective of the in-situ test was that the construction material used for the sealing structure (magnesia concrete) would swell during hardening and would thus be braced in the rock (build-up of a source pressure). In contrast to the successful laboratory tests previously carried out, this objective could not be achieved in the in-situ test carried out in the Bleicherode mine.

The BfS is currently examining why the source pressure of the magnesia concrete has developed differently in the laboratory tests and in the large-scale test. In practice, especially the production or, respectively, the mixing ratio of a suitable material and the handling of the mixing and conveying are key factors that decide whether the material will get the desired characteristics or not. The BfS also tested and used different recipes in the stabilisation of the central part with the help of salt concrete between 2003 and 2011. On account of the experiences made in this context, the recipe and the procedure were adapted to the real use.

The necessary modifications for the sealing structure in the anhydrite are determined from the examination results on magnesia concrete. Subsequently, a modified sealing structure will be built and put to the test in an in-situ test. Therefore, the BfS is currently examining adapting the used construction material and the construction principle.

State of 2016.07.22