Site Monitoring

The main task of site monitoring is the assessment of the geotechnical safety of the Asse mine during operation and the post-operational phase within the framework of preservation of evidence.

A geotechnical stability analysis consists of three parts that supplement each other equivalently:

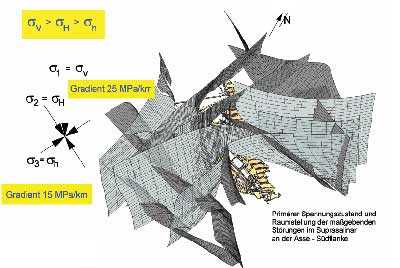

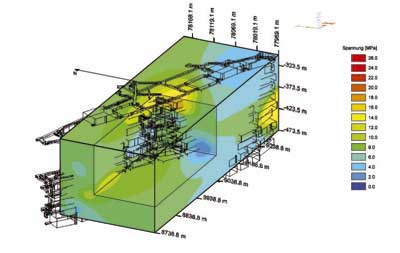

- Geomechanical analysis of the experiences gained from comparable excavations on stress and deformation behaviour of the surrounding rock

- Development of rock mechanical models and calculations of the stress and deformation behaviour by means of analytical and numerical procedures and methods

- Control of the predicted stress and deformation behaviour by in-situ measurements

Subjects

1 Determination of geotechnical parameters

1.1 Determination of material parameters and material behaviour for salt and overburden rocks

- by laboratory and pilot-plant experiments

- by in-situ measurements

1.2 Determination of soil mechanical parameters and material behaviour for the backfill

- by laboratory and pilot-plant experiments

- by in-situ measurements

1.3 Determination of the compaction behaviour of the backfill material used for assessment of the backfill effectiveness

2 Geotechnical stability of the Asse mine during operation

Assessment of the stability of the underground workings and of the surrounding rocks on the basis of experiences, in-situ measurements and rock mechanical model calculations for the operational phase

3 In situ-stress measurements

- Evaluation and assessment of in-situ stress measurements in salt

- Stress measurements in bearing elements of the underground workings (pillars, hanging walls, southern and northern walls)

- Check and control of the calculated time-dependent stress conditions of the bearing elements of the underground workings and the rocks in the area between salts rock and overburden strata

- Verification of effectiveness of backfill measure

4 Geophysical monitoring

4.1 Geophysical monitoring of the underground structure

- Determination and observation of geophysical relaxation processes

- Determination and investigation of wetting of the backfill and humidity penetration in the near field of selected areas

- Identification of movements in the overburden

- Verification of effectiveness of backfill measure

4.2 Geophysical investigation in the surrounding area of the underground workings

- Clarification of brine migration paths

5 Quality assurance within the closure operation

With the backfilling of the chambers in the younger halite at the southern flank with residual salt, an important contribution was made to the further safety of the underground workings during the operational phase. From the point of view of GSF, the work to be performed within the framework of the closure of the Asse mine shall be started as soon as possible to ensure a safe closure of the former mine as scheduled. Therefore, in 2003, GSF applied for backfilling the workings in the deep part of the mine up to the 775 m level directly after backfilling the chambers in the southern flank.

To ensure performance of the closure activities on schedule and according to quality standards, a quality management system (QMS) was introduced at the Asse mine. Quality assurance according to DIN EN ISO 9001:2000 is binding for all areas and disciplines of the Asse Research mine. It ensures the quality assured control and state of the art for all constructional measures to be performed on the surface and underground.

For further backfill measures, a qualification and quality assurance plan with

- description of the accompanying quality-assuring inspections,

- demonstration that the required targets have been met in terms of quality and quantity,

- monitoring of technical implementation, and

- preservation of evidence and documentation,

have to be developed.

6 Safety of Shaft # 4

- Control of the deformation behaviour of the shaft contours

- Assessment of operational safety